New Build

Respecting the hierarchy of a farmstead

Completed in 2017 this large family home, adjacent to listed farm buildings, was built on a disused agricultural plot in the Kent countryside. The veil of louvres wrap around the main house and give the sense that this may still be an agricultural barn.

Materials

Exterior

Two single storey timber and mathematical tiled barns define a public courtyard on entering the site and a private courtyard on the south east side of the house.

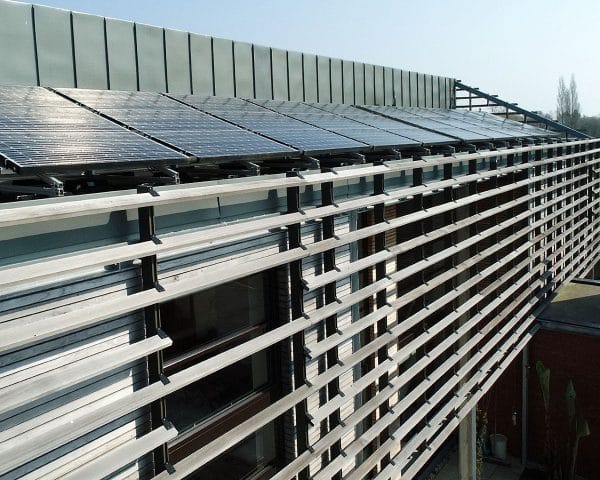

The PV-T panel mounted on the roof harness solar energy as electricity and heat. The heat is extracted and dumped beneath the Paragraph 84 (Para 55) building into the Earth Energy Bank, inter seasonal heat store which will heat the house during the winter months.

Plan arrangement

Formal arrangement separates south facing arrival & private garden spaces

Technology

Sustainable Timber Construction

Like all HAWKES projects, Echo Barn is built upon rigorous low carbon design principles; both in its efficiency in use and in the use of low embodied carbon materials in its construction. In collaboration with a highly experienced timber frame engineer we built a 3d model of the frame which enabled us to optimise its construction efficiency. We could also coordinate the MVHR ductwork into the frame so that the installation would be fully resolved prior to construction on site.

Like all HAWKES projects, Echo Barn is built upon rigorous low carbon design principles; both in its efficiency in use and in the use of low embodied carbon materials in its construction. In collaboration with a highly experienced timber frame engineer we built a 3d model of the frame which enabled us to optimise its construction efficiency. We could also coordinate the MVHR ductwork into the frame so that the installation would be fully resolved prior to construction on site.