Principles

Reduced Embodied Energy

The embodied energy study of the Crossway Passive House which was undertaken by Cambridge University back in 2009 provided an invaluable insight into the energy expended to build a uniquely designed house. This knowledge has underpinned the practice’s work ever since and has enabled all Hawkes projects to be exceptional in their energy conservation both in construction and in use.

The embodied energy study of the Crossway Passive House which was undertaken by Cambridge University back in 2009 provided an invaluable insight into the energy expended to build a uniquely designed house. This knowledge has underpinned the practice’s work ever since and has enabled all Hawkes projects to be exceptional in their energy conservation both in construction and in use.

Education

Carbon footprint results

The total estimated embodied energy for the entire build, was calculated to be approximately 900 GJ, equivalent to 250,000 kWh and given the project floorspace covered 285m2, this worked out to be 877 kWh/m2. This estimate was based on material components, (I) the solar PV-T panels and (II) the transportation of the construction team.

From the results, it was clear to see that the vast majority of the embodied energy came from just 5 key materials.

EPS (which is expanded polystyrene foam, a rigid insulation material), the PV-T solar panels, concrete, clay tiles and cement, which constituted to over 80% of the total embodied energy. However the other 20% of the entire carbon footprint, was made up of transportation costs, which is often overlooked but makes up a huge percentage of the overall footprint.

We simplify detail and minimise heat loss

Onsite

Reduce materials & waste

Why use more materials than is required to do the job? Whilst it is right to be seeking to use materials with a low embodied energy footprint it is also responsible to use materials sparingly. We dislike the notion of using extensive quantities of timber. For instance when using CLT (Cross Laminated Timber) and celebrating how much CO2 is being locked into the building without questioning the face that you’re using 10 times more timber than was necessary.

Why use more materials than is required to do the job? Whilst it is right to be seeking to use materials with a low embodied energy footprint it is also responsible to use materials sparingly. We dislike the notion of using extensive quantities of timber. For instance when using CLT (Cross Laminated Timber) and celebrating how much CO2 is being locked into the building without questioning the face that you’re using 10 times more timber than was necessary.

Visualisation

Construction Efficiency

So many techniques have improved over recent years and we continue to develop these innovative concepts today. Benefiting from VR and 3D computer modelling, we can now visualise the construction process, with both the client and main contractor to increase the speed of our developments and the productivity on-site.

Detailing

Cold bridging & airtightness

We have recognised the importance of air tightness in reducing heat leakage from the building envelope and so we have been adapting and innovating various construction details to make building airtight easier and more attainable to contractors less familiar with airtight passive house construction techniques. Here are examples of some of these innovations which collectively make a significant contribution to reducing operational energy in our buildings.

We have recognised the importance of air tightness in reducing heat leakage from the building envelope and so we have been adapting and innovating various construction details to make building airtight easier and more attainable to contractors less familiar with airtight passive house construction techniques. Here are examples of some of these innovations which collectively make a significant contribution to reducing operational energy in our buildings.

Mitigating the use of steel where possible

Resources

Sustainable local materials

Many building products are made from finite resources and two examples of this are sand and insulation. We believe buildings should use recycled materials where possible and specify both Ecosand and Cellulose as viable alternatives.

Ecosand is made from recycled glass bottles and is a perfect sharp sand substitute. Doesn’t use a virgin natural resource and makes use of a large volume bi-product of every day life.

Cellulose insulation is made from recycled newspapers and magazines. It gets mixed with Borax to provide, fire resistance and protection from vermin, has excellent U-values and is a brilliant use of a waste material in plentiful supply.

Glass

Triple & quadruple glazing

We always specify triple, or even quadruple, glazing on our projects, as this is one of the most significant investments a client can make into the fabric of their building. The benefits are multifaceted, not only are the U-values significantly better, saving energy through lower heat loss, triple glazed casement units reduce noise, reflect heat and are generally better sealed which reduces draughts.

We always specify triple, or even quadruple, glazing on our projects, as this is one of the most significant investments a client can make into the fabric of their building. The benefits are multifaceted, not only are the U-values significantly better, saving energy through lower heat loss, triple glazed casement units reduce noise, reflect heat and are generally better sealed which reduces draughts.

Improved

Passive solar gain

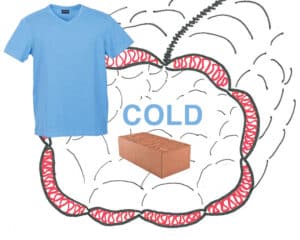

Most UK houses don’t wear enough clothes. Houses with ‘T-Shirts’ need lots more energy to stay warm in Winter as they have little mass to store the daytime solar gains. With limited heat storage the internal space will cool down quickly.

Our houses wear ‘Ski Jackets’ are air tight and are built from insulated timber frames. Houses with ski jackets are easier to keep warm in Winter. The sleeping bag analogy represents a continuous uninterrupted insulation layer around the floor, walls and roof. This keeps the heat in and the cold out. Sun warms air, and the mass inside the sleeping bag stays warm during the day.